Mark,

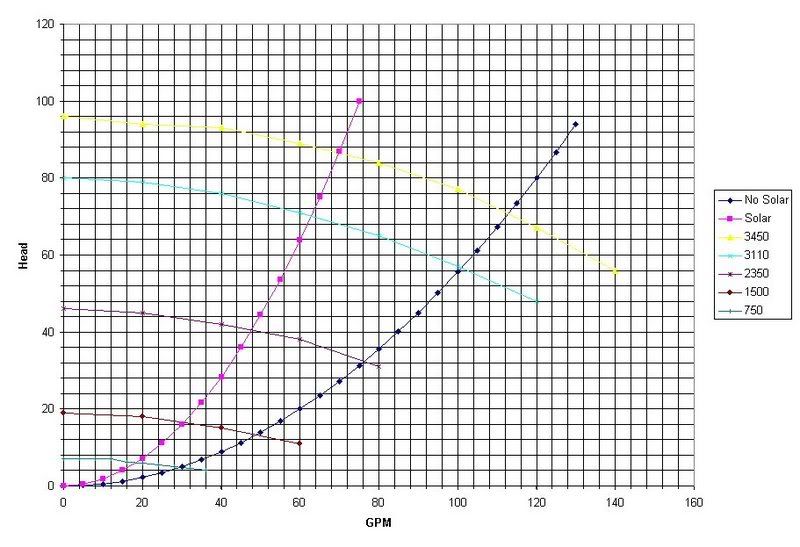

I also made a spreadsheet which is how I came up with the formula, and I carefully measured the graphs with a ruler to get reasonable accurate numbers. My data, from both the full IntelliFlow and the IntelliFlow 4x160 graphs, is as follows:

(I'm continuing to edit this to straighten out the columns)

Code:

GPM Head Out. Power In. Power Eff. (RPM/350)^2-(GPM^2)/470

(ft.) (RPM/322)^3+80

3450 RPM

0 96 0 1310 0.0% 97.180164 1310.277154

20 94 353.7502 1620 21.8% 96.32910017

40 93 699.9738 1930 36.3% 93.77590868

60 89 1004.8011 2210 45.5% 89.52058953

80 84 1264.4688 2510 50.4% 83.56314272

100 77 1448.8705 2780 52.1% 75.90356826

120 67 1512.8466 2980 50.8% 66.54186613

140 56 1475.2136 3010 49.0% 55.47803634

3110 RPM

0 80 0 78.95591837 980.9766836

20 79 297.3007 78.10485454

40 76 572.0216 75.55166305

60 71 801.5829 71.2963439

80 65 978.458 65.33889709

100 57 1072.5405 57.67932262

120 48 1083.8304 48.3176205

2350 RPM

0 46 0 45.08163265 468.7191816

20 45 169.3485 44.23056882

40 42 316.1172 41.67737733

60 38 429.0162 37.42205818

80 31 466.6492 31.46461138

2070 RPM

0 35 0 330 0.0% 34.97877551 345.6705539

20 34 127.9522 450 28.4% 34.12771168

40 32 240.8512 550 43.8% 31.57452019

60 28 316.1172 630 50.2% 27.31920104

80 22 331.1704 690 48.0% 21.36175423

1500 RPM

0 19 0 18.36734694 181.0895264

20 18 67.7394 17.51628311

40 15 112.899 14.96309162

60 11 124.1889 10.70777247

950 RPM chart said 750, but was probably wrong

0 7 0 7.367346939 105.6804838

20 6 22.5798 6.516283109

690 RPM

0 4 0 95 0.0% 3.886530612 89.83965015

20 3 11.2899 95 11.9% 3.035466782

I do not get the same data you do in your table for actual GPM. For example, at 3450 RPM and a head of 80 feet, the graph looks like this is 90 GPM, not the 97 "Actual GPM" shown in your table. I understand the pump affinity equations that are valid in regions of equivalent efficiency. I just was curiously looking for a general solution. I believe what I said before to be true, that the formula I came up with is within 1-2 feet of head in accuracy which probably means that it is accurately reflecting what is going on -- a static head based on RPM^2 minus a dynamic head based on GPM^2. The "static head" is really a balanced dynamic head between the motor pushing water one way and it leaking at the same rate the other way. The GPM^2 term appears to just be the dynamic head of the net amount of flow through the pump so while the RPM^2 "push" amount remains constant (since we are looking at a curve at constant RPM), the "leakage" amount decreases as the head decreases so that a net GPM increases. Or another way of looking at it is that the pump RPM is pushing water at a GPM determined from (RPM/350)^2-(GPM^2)/470 = 0; GPM = sqrt(470*(RPM/350)^2) = RPM/16.1 so at 3450 this is 214 GPM. So the pump's RPM (and impeller size) cause 214 GPM to move when there is no head. Any resistance (head) results in a backward "leakage" which causes the net GPM to drop (since this backward movement meets a lot of frictional resistance), but 214 GPM is always being moved "forward" by the pump even when the net GPM is 0 (meaning that the "leakage" is also 214 GPM so no net movement is seen). At least this is my best understanding of how this works. I don't have the pump curves (for this pump) going down towards 0 head, but I have seen other pumps' curves that do appear to have the parabolic shape (see this link, for example).

Regardless of which formula is used, I also wanted to estimate the electrical efficiency and that has been harder to determine. Unfortunately, only 3 RPMs showed electrical power curves on the graph so my best-guess formula isn't validated very well, but it does appear to roughly be a combination of some small fixed losses (resistance, probably) plus an amount of "work" that is related to the cube of the RPM. This makes sense since the velocity of water is proportional to the RPM as is the GPM (as shown with the formula in the previous paragraph) while the frictional losses (i.e. head) are roughly proportional to the GPM^2 so the power is expected to be the product of the flow rate times head so proportional to GPM^3 and since GPM and RPM are directly related, this is proportional to RPM^3. What is harder to figure out is how the electrical power doesn't track the output power or the amount of head as might be expected. It instead seems to have a linear increase with net GPM and then slows down its increase as it approaches around 50% efficiency. I would presume that eventually as output power dropped at lower GPM, that the electrical power would start to drop as well. The electrical power should be directly related to the pressure resistence against the impellers (I'm assuming a constant RPM) which is a difference in pressure on one side of the impeller compared to the opposite side. So normally one would expect the electrical power to be proportional to head alone, but apparently the "leakage" causes some of the pressure on the opposite side of the impeller to be higher so that the net difference isn't the full amount of head (so there is less net pressure and therefore less "work"). As the head declines, the leakage also declines and apparently reduces the pressure on the opposite side of the head faster than the overall head drop so that there is a net electrical power increase. Near the point of optimal efficiency, these two effects act so that the amount of electrical power tracks the output power (near 50% efficiency) which essentially means that the "leakage" reduces the back pressure faster than the drop in overall head, but at a rate that is similar to the output power. I suspect that in the region at lower head and high GPM that the electrical power drops in rough proportion to the head since the "leakage" effect would be much smaller at that point. So, at very low head, the pump curve should be near vertical instead of the parabolic formula that I came up with (assuming that the leakage becomes minimal at low head). It seems like I'm missing something here, at least for figuring electrical power -- either that or it truly is as complicated as it sounds and not easily computed.

Richard

Reply With Quote

Reply With Quote

Bookmarks